Using IronCAD, the company creates and stores the intelligent parts within its parts catalog.

“So, we have a high level of automation within our company.” “To move from design to the finished products very fast, we have to be very flexible,” he says.

#IRONCAD DRAWING TEMPLATE NOT SOFTWARE#

To stay ahead of competitors, the company delivers its products quickly after they receive an order, “Even going to the point to state if they need to deliver the next day, they will deliver the next day ,” says Eddy Huis in’t Veld, the company’s software manager. Van Keulen maintains manufacturing facilities for processing wood, metal, and plastic. The company can manufacture and customize almost any interior element to meet customer requirements. Credit: Van Keulen InterieurbouwĬustomer needs vary according to the layout and the look they seek. Van Keulen Interieurbouw, which makes office fixtures and furniture, is able to customize designs and get them into production quickly by integrating its CAD tool with its ERP system. Take the example of Dutch company Van Keulen Interieubouw, which makes fixtures and equipment for retail and office environments, including shelving units and cashier stations made from materials like wood and laminate.

Still others use IronCAD as their design system. Others have used it as a backbone of their own proprietary software. Some companies have integrated IronCAD software with their enterprise systems for even greater hands-off customization. The already-designed parts can be dropped within many popular CAD programs as well as into IronCAD designs, he says.

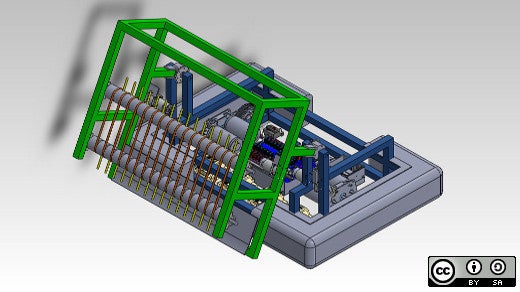

#IRONCAD DRAWING TEMPLATE NOT HOW TO#

If you want to make it larger, the tool knows how to update the part to make that change,” O’Connor says. “Rather than insert constraints to the part, we’re doing it on the fly, positioning and changing information at the same time. This is what allows the drop-in and automatic fit, he adds. The designer need not worry about that step. The CAD maker calls these cataloged parts “intelligent parts” because they contain the geometry and other information to fit the assembly seamlessly. Assembly part data is integrated into a file’s design rather than linking to external files, O’Connor says. The catalog of parts requires only one file, no matter how complex. “But engineers can use these parts confidently without worrying about how the original design was created,” O’Connor says. “We can do that, but with us, you can also drag-and-drop parts and assemblies from a catalog into the design environment, mesh the geometry, and use that for enhanced CAD design.”Įngineers do, of course, need to create the original file for the frequently used parts and assemblies, which are then stored in the catalog, from which they can be pulled from for use again and again. “In traditional CAD, you start with a sketch, put it into a 3D profile, you insert parts from a file system and you keep drawing like that,” he adds. The piece from the catalog provides precise reference locations when designers drop their components into a larger design, positioning it automatically into any complex orientation required, O’Connor says. With this method, feature, part, and assembly data for each part are stored in a catalog of frequently used parts and assemblies. While today’s CAD systems continue to add that functionality, IronCAD was the originator of the concept with the company’s launch in 1998, says Cary O’Connor vice president of marketing at IronCAD, Atlanta. With configuration-based design, the CAD file automatically sizes and fits itself into the assembly. That’s the idea behind configuration-based design, which allows users to drop an already-created design file into a part or assembly for quick customization. Many companies, particularly those that create custom parts or manufacturing systems, integrate already-created CAD parts into an assembly to shave design time. You could, for instance, drop the computer-aided design file for an existing wheel into your lawnmower design. Sometimes you don’t need to re-invent the wheel. Repurposing designs saves design time and money, helping you get to market faster.

0 kommentar(er)

0 kommentar(er)